Alstone Classic

ACP Sheet

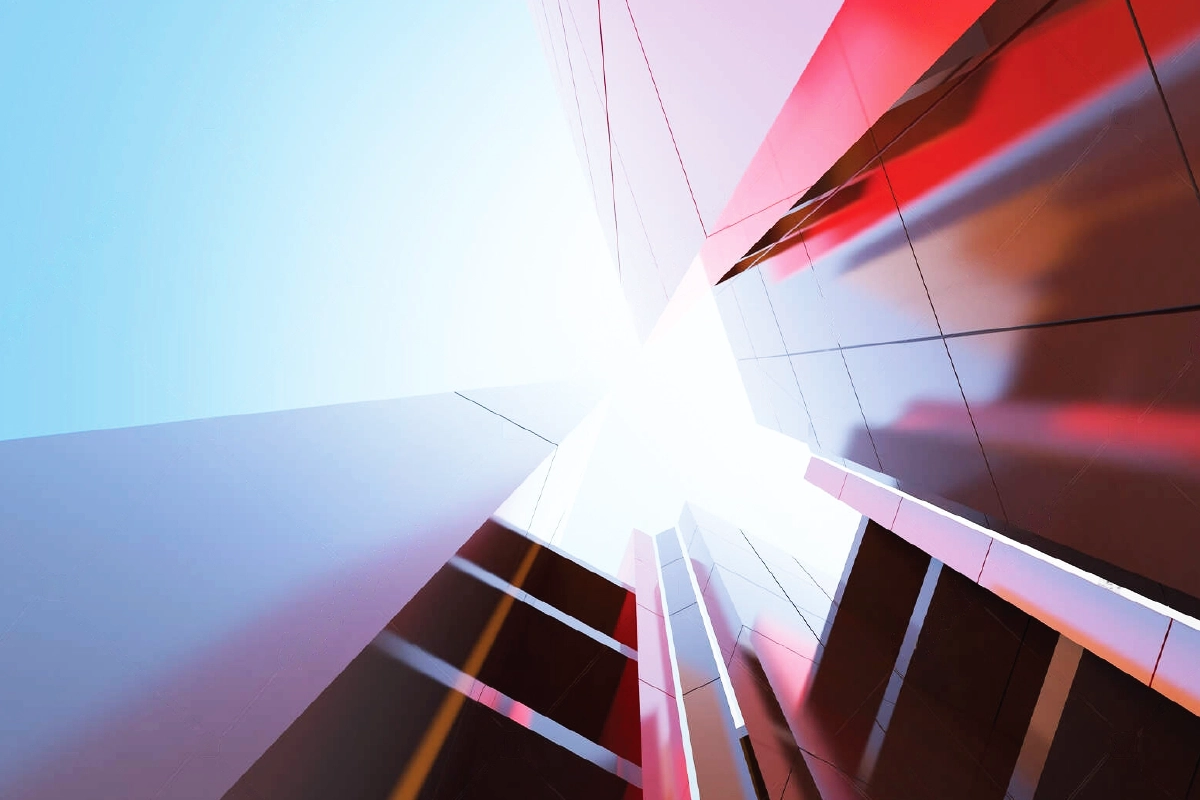

Aluminium Composite Panel (ACP Sheet) are a modern marvel in building materials. They consist of two thin layers of aluminum bonded to a core of non-metallic material. This unique structure offers unmatched durability and aesthetic flexibility, making ACP sheet perfect for a wide range of applications, from sophisticated facade cladding to stylish interior decorations.

Before

After

Benefits

Maintenanace Free

Easy Installation

Ready to use

Water & Termite Proof

Wide Range of Colours

Applications

Canopy

Exterior Cladding

Interior Design

Fence & Railing

Explore Our Shades

-

VL-01 Signal Red

-

VL-02 Yellow

-

VL-03 Orange

-

VL-04 Bright Silver

-

VL-05 Champagne Silver

-

VL-06 Champagne Gold

-

VL-07 Metallic Silver

-

VL-08 Bright White

-

VL-10 Ivory White

-

VL-11 Dark Blue

-

VL-12 Light Blue

-

VL-13 Blue Silver

-

VL-14 Black Silver

-

VL-15 Copper Metallic

-

VL-16 Lilac

-

VL-17 Brush Silver

-

VL-19 Coal Black

-

VL-20 Metallic Bronze

-

VL-21 Jade Metallic

-

VL-22 Super Gold

-

VL-23 Ocean Green

-

VL-24 Magic Gold

-

VL-25 Traffic Yellow

-

VL-26 Brick Red

-

VL-27 Wine Metallic

-

VL-28 Dabar Green

-

VL-29 Rose Metallic

-

VL-30 Choco Brown

-

VL-31 Coffee Silver

-

VL-32 S.S. Finish

-

VL-34 Golden Mirror

ACP Sheet, a premium building solution crafted by Alstone, a leading ACP sheet manufacturer, showcases this robust versatility. Our ACP Sheets stand out for their exceptional dimensional stability, variety of finishes, and vibrant colors that cater to any architectural vision.

Ideal for both new construction and renovations, these ACP Sheets are the preferred choice for architects and builders seeking the best in ACP cladding and ACP panel solutions. They distinguish themselves as a key element in modern construction and design, delivering functionality and flair.

Benefits

Experience the Alstone Classic advantage with our ACP sheets, where innovation meets sustainability. Engineered by Alstone, a premier ACP sheet manufacturer, these Aluminium Composite Panels are a testament to the sophistication and robustness required for today's architectural demands.

Designed for both functionality and aesthetics, these sheets are lightweight and come with a robust 15-year warranty. Our sheets are India's first aluminum-based HPL Sheet, featuring a Lumiflon coating for enhanced durability. This makes them recyclable, termite—and fungus-proof, and UV-resistant. They are ideal for diverse applications and ensure easy installation and long-lasting performance in all weather conditions.

For a maintenance-free solution that stands the test of time, choose Alstone Classic - ACP Sheets—a hassle-free solution for all your design needs.

Alstone Classic Gallery

Presenting a visual feast of possibilities, displaying the exceptional adaptability and range of our ACP sheets.

From modern facades to stylish interiors, this expansive collection highlights the functional beauty of our sheets in real-world applications.

Witness how these panels enhance architectural designs, inspiring your next project with varied textures and colors.

Applications

Alstone Classic - ACP Sheets, crafted by Alstone, a leading ACP sheet manufacturer, offer unmatched versatility and reliability. These high-quality aluminum composite panels excel in a wide range of applications, ensuring that architects and builders can confidently implement them across diverse projects.

These sheets ensure durability and style and are perfect for external ACP cladding, internal design elements, and creating signage with stunning ACP panels.

Their lightweight yet sturdy build makes them ideal for innovative uses in canopy construction, fencing, railing, and countless applications where adaptability is essential.

Explore Our Shades

Colors hold the power to shape the character of a space. That's why Alstone Classic ACP sheets offer a curated selection of colors and finishes that are designed to complement any architectural style.

From the subtle elegance of 'Perlato' to the vibrant punch of 'Champagne Gold,' the warm earthiness of 'Natural Mahogany' to the cool serenity of 'California Teak,' our shades are designed to make a statement!

These sheets are not only visually stunning but also boast properties like weather and UV resistance, termite protection, and antibacterial qualities, making them a reliable choice for both interior and exterior applications. Transform your space with our stunning, maintenance-free shades, which promise to deliver on both performance and aesthetics.

Conclusion

As you explore and consider the many benefits of Alstone Classic ACP Sheets, meticulously crafted by Alstone, a leading ACP sheet manufacturer—for your next project, remember that these Aluminium Composite Panels are more than just a building material; they represent the pinnacle of design flexibility and structural durability.

These panels have been designed to meet the highest standards of aesthetics and functionality. Ideal for applications such as ACP cladding and ACP panels, Alstone Classic brings a modern touch to buildings with its wide range of colors and finishes. It ensures that each project achieves a distinctive look while benefiting from enhanced longevity and minimal maintenance requirements.

Incorporating Alstone Classic ACP Sheets into your projects means embracing innovation, durability, and design excellence. Opting for these sheets ensures a commitment to sustainable building solutions that align seamlessly with contemporary construction standards and practices. This makes them an excellent choice for forward-thinking architects and developers who prioritize quality, sustainability, and style.

Frequently Asked Questions

Q1. Alstone ACP Sheet Classification

Ans.

Alstone ACP sheets are classified into two types based on their usage and fire rating standards.

- Non-flammable grade

- A2 grade / fire-rated grade

Q2. Non-Flammable Grade Aluminium Composite Panel Sheets

Ans.

Aluminium Composite panels are made up of two thin layers of aluminium sheets sandwiched by a polymer core. The polymer core of an Aluminium Composite Panel is typically made of Low-Density Polyethylene (LDPE) or Polyurethane & Alstone offer different skin core thickness depending on one’s requirement.

Q3. Aluminium Composite Panel - Fire-Rated Grade - Called A2

Ans.

Depending on the core material, the fire-rated Aluminium Composite Panel can withstand a fire for up to 2 hours. The primary distinction between fire-rated ACP sheets manufactured by Alstone and standard ACP sheets is in the core materials. The Standard ACP's core is made of LDPE/HDPE, whereas the fire-rated ACP has a specially formulated fire-resistant mineral core. Magnesium hydroxide is commonly used as a core for superior fire-retardant properties.

However, as the name implies, Fire Grade Aluminium Composite Panels have the unique property of withstanding high temperatures.

It is important to remember that the highest-grade ACP is fire retardant ACP (A2 GRADE), which contains nearly 90% inorganic mineral content.

Q4. Aluminium Composite Panel Benefits

Ans.

Aluminium Composite Panels are widely used nowadays due to a variety of distinct properties. Here are some of the distinguishing characteristics that set it apart from other comparative panelling materials.

Q5. Lightweight

Ans.

In comparison to steel and other construction materials, the ACP sheet is lightweight. With large spans and large areas involved, this drastically reduces the design loads on the structure. ACP sheets are lightweight and simple to lift and erect. Overall, this reduces manpower and construction costs while keeping the project on schedule.

Flexible ACP sheets are highly adaptable and simple to work with. The fixing framework assembly is straightforward, and installation is simple and quick.

Q6. Color Options and Availability

Ans.

The variety of finishes available with this composite panel gives it exceptional versatility. Aluminium composite board can be textured, solid, mirror, or wood type to match any architectural theme. In general, the colour and texture of real stone and wood can be made of.

Q7. Environmentally Conscious

Ans.

An ACP sheet is an environmentally friendly material that is composed of 85% recycled aluminium. Furthermore, the ACP core material and cover sheets can be reused indefinitely.

Q8. Dimensional Consistency

Ans.

Overall, ACP sheets have high dimensional stability, and the material can be stable for a long time without changing dimensions.

Q9. ACP Sheet Cost

Ans.

When compared to other panelling materials, ACP sheet is the most cost-effective option. The price is determined by the primary materials. Naturally, Fire-rated materials will be more expensive than standard non-fire-rated ACP.

ACP panels are weather resistant and durable. They are basically unbreakable, stain-resistant, weather-resistant, termite-resistant, moisture-resistant, and anti-fungal.

Q10. Applications of Aluminium Composite Panel Sheets

Ans.

Because of its exceptional properties, ACP sheet is primarily used for a wide range of applications. The ACP sheet has the following major applications.

Architectural cladding, both external and internal

- False Ceilings for HVAC needs in offices

- Signage

- Covering frameworks for protecting machines

- Container building

- Architectural cladding/facade, both external and internal

Because of their diverse properties such as UV resistance, fire resistance, and durability. ACP sheets are generally available in a wide range of colours to complement any architectural theme. The lightweight properties, simple fixing methods, and quick construction make ACP sheets the preferred choice for facades/partitions.

Q11. Interior Design

Ans.

Interior applications for ACP sheets include wall coverings, false ceilings, cupboards, portable kitchen cabinets, tabletops, column covers, and more.

Q12. An FR Composite Panel is the Ultimate in Safety and Sustainability.

Ans.

Aluminium composite panels are fire retardant, environmentally friendly, easy to clean, and can reduce construction time in half.

Above all, ACP panels are corrosion resistant and prevent acid and alkali corrosion, as well as other types of corrosion.

ACP sheets are a popular choice in the construction industry due to their versatile properties.